Conveyor Belt Ploughs

Diagonal Ploughs

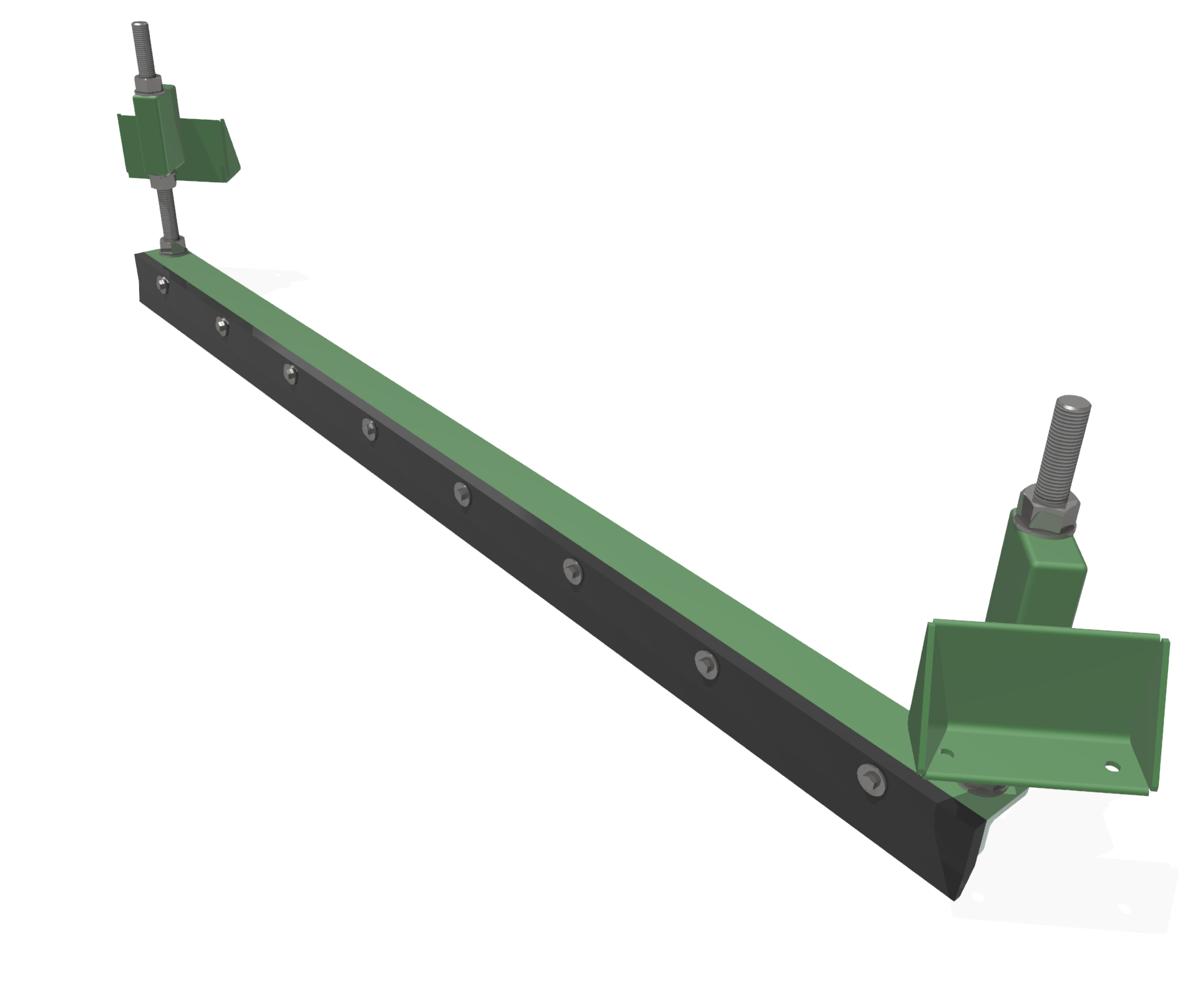

The BBCP Diagonal Plough is designed to be positioned on a flat, stable section of belt, in close proximity to a tail pulley, upper counterweight bend pulley, or anywhere that spillage on the return side of the belt needs to be removed. It is typically referred to as a return belt cleaner, as it operates on the return side of the belt. The Diagonal Plough comprises a pair of mounting brackets with mounting shafts, the plough frame and a bolt-on poly blade. The blade is 100mm high with 50mm of usable blade.

Although BBCP Diagonal Ploughs can handle reversing belt applications, they will not work well in a reversing application. (A BBCP Reversal Plough can handle reversing belt applications.)

In some applications, large materials may be required to be handled by the plough. In such circumstances, a Stone Guard can be added to the frame. For complicated applications contact Belle Banne Conveyor Products for more information.

Return belt cleaners significantly reduce the amount of material, that has spilled onto the return belt, from building up on the tail pulley (or other pulleys at similar risk). They also provide protection from foreign objects (e.g. failed rollers) travelling through the pulley and damaging the belt and pulley lagging.

These issues contribute to unwanted plant downtime, resulting in increased costs. Installation of appropriate return belt cleaners will minimise these issues.

Features & Benefits

- Deflects material from the inside of your belt, protecting your tail pulley and belt

- Available in for belt widths 450mm up to 2400mm

- Available with UHMW blades for long life, or FRAS urethane for underground applications

- Flexibility in the set up angle

- Mounting brackets can be installed either under or over the conveyor structure

Coal, Iron Ore, Hard Rock, Heavy Metals, Sand and Gravel, Recycling, Power Generation and Steel Mills. Contact BBCP for more information on your application.

| BELT WIDTH (mm) | ITEM CODES |

| 450 – 750 | 231201 |

| 900 – 1050 | 231202 |

| 1200 – 1500 | 231203 |

| 1600 – 2000 | 231204 |

| 2100 – 2400 | 231205 |