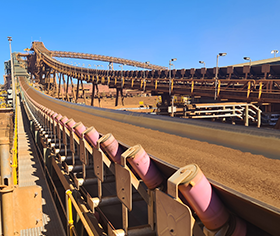

Conveyor Belt Cleaners

PHS SST-I Secondary Belt Cleaners

The Belle Banne® PHS (P High Speed) SST-I (Inverted Secondary Spring Tensioner) Belt Cleaner is typically referred to as a “secondary” cleaner, as it is usually installed in conjunction with a “primary” belt cleaner that is located at the material discharge point. It is designed to be positioned on a flat, stable section of belt in close proximity to the head pulley or a flat return and/or hold down roller. The PHS SST-I is ideal in areas where mounting bracket space is limited below the pole.

It comprises a pair of side assemblies, a pole and a series of “blades” each comprising a rubber cushion and a tungsten tip. The blades are 150mm wide. PHS SST-I Belt Cleaners can handle reversing belt applications where the belt occasionally travels backwards (such as trippers), however they are not suitable for belts where the material flows in both directions.

The Spring Tensioner extends the period between adjustments in applications where high tip wear is an issue. For more challenging applications, multiple PHS Belt Cleaners can be installed in close series.

Available to suit your belt widths from 450mm to 3000mm, in stainless or mild steel, the PHS SST-I Belt cleaner will satisfy your cleaning needs.

COMBI-LITETM

Every cleaner in our P & PHS Belt Cleaner range is also available with a Combi LiteTM pole. Utilising proprietary manufacturing techniques, Combi LiteTM poles are produced in a way that minimises localised stresses and are up to 70% lighter than equivalent steel poles.

An additional benefit of our Combi LiteTM pole is that it can be used on either H-LITETM, P-LITETM or PHS-LITETM belt cleaners, providing you with an opportunity to reduce inventory costs.

Features and Benefits

- 3 different tip sizes available 10, 15 and 25mm to suit different maintenance schedules

- Tried and tested cushion design

- Cost effective due to cushion and tip life consistency

- Suitable for high speed belts and abrasive materials

- Can be installed where there is limited room and in difficult applications

- High quality standard components

- Spring tensioner extends the timeframe between adjustments compared to a bolt tension side assembly

- Inverted assembly is ideal where there is limited mounting bracket space below the pole

Coal, Iron Ore, Hard Rock, Heavy Metals, Sand and Gravel, Recycling, Power Generation and Steel Mills. Contact BBCP for more information on your application.

| BELT WIDTH (mm) | BLADE WIDTH (mm) |

POLE LENGTH (mm) |

POLE DIA (mm) | ITEM CODES | |||

|---|---|---|---|---|---|---|---|

| MILD STEEL (EL-25) | STAINLESS STEEL (EL-25) | ||||||

| 450 | 450 | 1450 | 73 | 120421 | Contact us for info | ||

| 600 | 600 | 1600 | 73 | 120422 | Contact us for info | ||

| 750 | 750 | 1750 | 73 | 120423 | Contact us for info | ||

| 900 | 900 | 1900 | 73 | 120424 | Contact us for info | ||

| 1050 | 1050 | 2050 | 73 | 120425 | Contact us for info | ||

| 1200 | 1200 | 2600 | 73 | 120426 | Contact us for info | ||

| 1400 | 1350 | 2800 | 73 | 120427 | Contact us for info | ||

| 1500 | 1500 | 2900 | 73 | 120428 | Contact us for info | ||

| 1800 | 1800 | 3200 | 73 | 120429 | Contact us for info | ||

| 2100 | 2100 | 3500 | 73 | 120430 | Contact us for info | ||

| 2500 | 2400 | 3900 | 73 | 120431 | Contact us for info | ||

| 3000 | 3000 | 4400 | 73 | 120432 | Contact us for info | ||