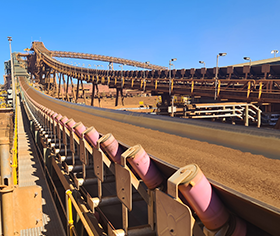

Conveyor Belt Fasteners

Plategrip™ Solid Plate Fastener

Plategrip™ Solid Plate fasteners are compression fasteners providing a strong durable splice. Without a hinge pin, the Plategrip™ fastener provides a sift-free splice and is also frequently used in rip repair applications.

The Traditional Plategrip™ teeth overlap the edges of the plates and provide extra holding power on thin belts. Passing smoothly over conveyor belt pulleys, Plategrip™ fasteners allow natural troughing of belts and smooth operation on both sides, through trippers and scrapers, as well as over crowned or takeup pulleys.

All buckets of solid plate fasteners have pre-assembled bolts and bottom plates that utilize our patented system, which includes the use of a special thin metal washer to clinch the bolt to the bottom plate during installation of the belt fasteners. This has proven to be superior to the use of plastic or nylon washers, which can slide along the bolt threads.

Steel – Plategrip™ Solid Plate Fasteners

Steel is the most common and economical belt fastener material and is the standard for most applications. Steel fasteners are manufactured in a broad variety of sizes and shapes, and are suitable for use in new equipment or as replacement fasteners.

Durgard – Plategrip™ Solid Plate Fasteners

Durgard is a special heat-treated steel with abrasion-resistant characteristics that provide several times the life of standard steel. Durgard Plategrip™ fasteners are not recommended for use in highly corrosive environments, but are instead specially formulated for abrasive situations.

Stainless – Plategrip™ Solid Plate Fasteners

Stainless Steel fasteners are best for applications where erosion is a major problem. Stainless steel is more resistant to abrasions, acids, chemicals, and magnetic attraction than standard steel. Plategrip™ fasteners are available in complete stainless sets, or with the top plate made of stainless steel and the balance standard steel.

FASTENER SELECTION CHART

| PRODUCT SIZE | MIN. PULLEY Ø | KN/M MAX | BELT THICKNESS (mm) |

|---|---|---|---|

| 1 | 300 | 30 | 0 – 1.6 |

| 140 | 350 | 40 | 5 – 11 |

| 190 | 450 | 65 | 8 – 14 |

| 1-1/4 | 350 | 30 | 11 – 17 |

| 1-1/2 | 450 | 30 | 11 – 18 |

| 2 | 750 | 75 | 14 – 21 |

| 2-1/2 | 1050 | 75 | 19 – 25 |

| 3 | 1200 | 100 | 24 – 30 |